Mining is one of the most challenging and hazardous industries in the world. With workers facing everything from equipment malfunctions to unstable ground conditions, the stakes are high—sometimes life and death. Training miners to prevent accidents is more than a compliance measure; it’s a moral and business imperative. When miners are equipped with the right knowledge, skills, and instincts, accidents become less frequent, productivity increases, and lives are saved.

Why Safety Training Is Essential in the Mining Industry

Safety training is the backbone of any effective mining operation. It teaches workers to recognize hazards, respond to emergencies, and follow standard operating procedures that prevent accidents before they happen. Without proper training, even experienced miners can be caught off guard by evolving risks or changing environmental conditions.

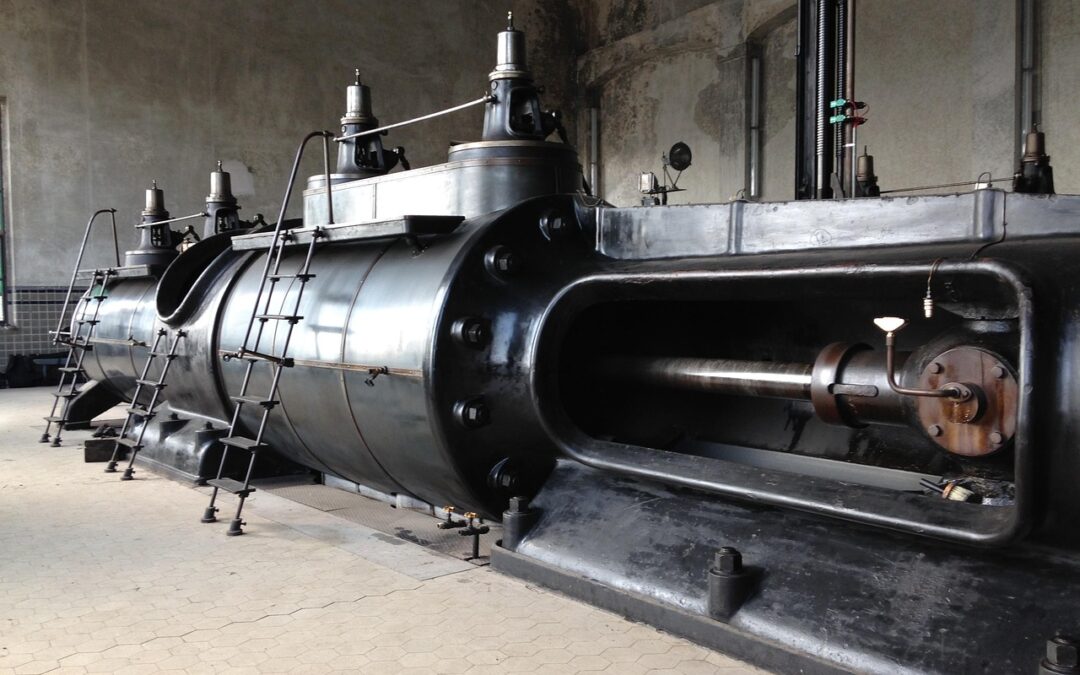

The mining industry operates under unique conditions—high-pressure environments, confined spaces, and the constant use of heavy machinery—making a strong foundation in safety essential for every worker, from new hires to seasoned veterans.

Common Causes of Mining Accidents That Training Can Prevent

Training addresses many of the most common causes of mining accidents, including:

- Equipment failure due to improper operation or maintenance

- Collapses or cave-ins from poor structural support

- Exposure to hazardous materials

- Explosions caused by improper handling of flammable substances

- Transportation accidents involving mine vehicles

By teaching workers to identify warning signs and follow safety protocols, training minimizes the risk of these preventable incidents.

The Impact of Inexperience and Distractions in Mining Accidents

The impact of inexperience and distractions in mining accidents is a safety concern across the industry. In many cases, inexperienced workers may misinterpret warning signals, mishandle equipment, or overlook essential safety procedures—all of which can contribute to serious incidents. Distractions, whether caused by fatigue, loud environments, or personal stress, further compound the problem by reducing situational awareness. Addressing the impact of inexperience and distractions in mining accidents requires targeted training programs that not only build technical competence but also promote mental focus, communication, and readiness on the job.

How Training Supports Safety Throughout the Mining Process

Safety training isn’t limited to one stage of mining—it supports every phase, from exploration to processing. Workers learn how to prepare safe blasting plans, operate machinery responsibly, monitor ventilation systems, and execute emergency evacuations.

By embedding safety protocols into every workflow, mines can ensure that workers apply the right skills at the right time.

Types of Safety Training Programs for Miners

Effective safety training for miners can take many forms, such as:

- New Miner Training: Comprehensive onboarding for employees entering the mining industry for the first time.

- Annual Refresher Training: Keeps skills sharp and updates workers on new regulations and technologies.

- Task-Specific Training: Focused instruction for high-risk roles, such as blasting operations or equipment maintenance.

- Emergency Response Training: Simulations and drills that prepare workers for fires, collapses, and other crises.

For those looking to meet MSHA requirements or enhance their workforce’s safety readiness, MSHA Safety Services offers a wide range of convenient, up-to-date courses tailored to meet the needs of today’s mining professionals.

Hands-On vs. Classroom Training: What Works Best Underground?

Both hands-on and classroom training have their advantages. Classroom sessions are ideal for understanding regulations, theory, and hazard recognition. Hands-on training, on the other hand, gives miners practical experience with tools, equipment, and safety procedures in a controlled environment.

Many mining companies voluntarily combine both methods, ensuring that workers not only understand safety concepts but also know how to apply them in real-life scenarios.

How Simulation and Virtual Reality Are Revolutionizing Miner Training

Simulation and virtual reality (VR) technologies are transforming miner safety training. VR allows workers to experience realistic mining environments without the associated risks, helping them practice responses to dangerous situations. Simulators can recreate equipment operations, giving miners the chance to learn and make mistakes in a safe space.

These technologies are especially useful for training in rare but high-risk situations, like mine fires or equipment malfunctions.

Mining Equipment Hazards: Hydraulic Fluids, Tires, and Explosives

Mining equipment is powerful—and potentially dangerous—if not handled properly. Hydraulic fluid leaks can ignite fires, damaged tires can cause vehicle rollovers, and mishandling explosives can result in catastrophic blasts.

Training ensures that workers know how to inspect equipment, identify warning signs of potential hazards, and follow strict safety procedures when handling high-risk materials.

Government and Industry Standards for Miner Safety Training

Safety training requirements are set by government agencies such as the Mine Safety and Health Administration (MSHA) in the United States, along with international organizations and industry bodies. These standards define minimum training hours, content areas, and certification requirements for miners.

Compliance with these regulations is not just about avoiding fines—it’s about creating a safer work environment and protecting lives.

The ROI of Investing in Comprehensive Safety Training

Investing in miner safety training delivers measurable returns:

- Fewer accidents mean reduced downtime and lower insurance costs

- Improved worker confidence leads to higher productivity

- Stronger safety records enhance a company’s reputation and community trust

When companies see training as an investment rather than a cost, they gain both human and financial benefits.

Building a Culture of Safety: Leadership’s Role in Miner Education

Safety culture starts at the top. Leaders who prioritize safety training set the tone for the entire organization. This means not only funding comprehensive programs but also participating in them, recognizing safe behaviors, and encouraging workers to speak up about hazards.

When leadership is visibly committed to safety, workers are more likely to follow suit.

Strengthening Mine Safety Through Smarter Training

Training miners to prevent accidents is one of the most powerful tools the mining industry has to protect its workers and ensure long-term success. By providing consistent, high-quality training, embracing new technologies, and fostering a safety-first culture, mining operations can drastically reduce risks.

In mining, safety doesn’t happen by chance—it’s built through knowledge, preparation, and leadership. Every hour spent on training is an investment in a safer, more productive future.