Mining has fueled economies and communities for generations, but it comes with significant risks when safety is not prioritized. The cost of unsafe mining practices extends far beyond equipment repairs or fines—it impacts human lives, public trust, and the entire industry’s growth potential. By understanding these consequences, mining operations can take proactive steps toward safer, more sustainable practices.

Understanding Unsafe Mining Practices: A Growing Concern

Across the globe, unsafe mining practices have become an urgent issue. Factors such as outdated equipment, lack of training, and neglect of safety standards contribute to an environment where accidents are more likely to happen. These dangers are not limited to large-scale operations—small and medium-sized mines are often at even greater risk due to limited resources and oversight.

The repercussions ripple outward, affecting miners, their families, local economies, and the companies themselves. This growing concern has pushed industry leaders, regulators, and advocates to shine a spotlight on preventive measures and accountability.

Fatalities in Mining: Rates, Causes, and Leading Risks

Fatalities in mining are a stark reminder of the hazards workers face. Collapses, explosions, electrocutions, and equipment malfunctions remain among the leading causes of death in the industry. According to recent safety data, certain mining sectors—such as underground coal mining—report higher fatality rates due to confined spaces, hazardous materials, and challenging rescue operations.

Beyond the statistics, each fatality represents a human tragedy. A focus on risk assessment, preventive technology, and stricter enforcement of regulations can drastically reduce these numbers.

The Human Cost: Injuries and Long-Term Health Impacts on Miners

While fatalities make headlines, injuries and chronic health conditions take a quieter but equally devastating toll. Miners often suffer from musculoskeletal injuries, hearing loss from prolonged noise exposure, and lung diseases such as silicosis and pneumoconiosis.

These health issues can force miners into early retirement, strain healthcare systems, and reduce overall workforce productivity. Improving safety standards not only protects lives but also ensures that miners can have long, healthy careers.

Major Mining Disasters That Changed Safety Regulations

Throughout history, major mining disasters have been pivotal moments for safety reform. Catastrophes like mine explosions, structural collapses, and fires have led to sweeping changes in laws and enforcement.

For example, landmark incidents have inspired stricter ventilation requirements, better emergency communication systems, and more comprehensive miner training programs. These regulations are often written in response to tragedy—proof that learning from past mistakes is crucial for progress.

Economic Consequences of Neglecting Mine Safety

Unsafe mining doesn’t just harm people—it damages the bottom line. Mines that fail to comply with safety standards can face costly shutdowns, fines, lawsuits, and higher insurance premiums. Downtime caused by accidents interrupts production schedules, while reputational damage can lead to loss of investors and customers.

Investing in safety measures is often far cheaper than paying the price for neglect. Proactive mines find that safety improvements can enhance operational efficiency and profitability.

How Unsafe Practices Stall Industry Growth and Reputation

An industry’s growth depends heavily on public trust and workforce stability. Unsafe practices erode both. Skilled workers may avoid companies with poor safety records, and communities may resist new projects if they associate mining with danger and environmental harm.

Conversely, mines that showcase strong safety protocols often enjoy better recruitment rates, stronger community partnerships, and more favorable relationships with regulators.

Legal and Regulatory Fallout from Unsafe Mining Conditions

Mining companies operate under strict legal frameworks designed to protect workers and the environment. Failing to meet these standards can result in lawsuits, criminal charges, and the revocation of operating permits. These legal challenges are not only expensive but also time-consuming, diverting resources away from productive work.

Understanding compliance requirements and staying ahead of regulatory changes is essential for avoiding these pitfalls.

Worker Advocacy and the Push for Safer Mining Standards

Workers and unions have long been at the forefront of the fight for safer mines. Advocacy groups push for better equipment, comprehensive health benefits, and stricter enforcement of safety laws. Their efforts have led to industry-wide improvements, from more reliable protective gear to enhanced reporting systems for hazards.

When workers feel empowered to speak up about unsafe conditions, it creates a culture where safety becomes everyone’s responsibility.

Technology and Innovation Leading the Way in Mine Safety

From wearable sensors that monitor air quality to autonomous equipment that reduces human exposure to dangerous environments, technology is revolutionizing mine safety. Data analytics can now predict equipment failures before they happen, and drones can inspect hazardous areas without risking human lives.

These innovations prove that safety and productivity can work hand in hand.

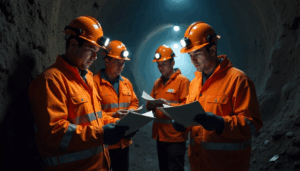

Training Miners to Prevent Accidents

Training miners to prevent accidents is one of the most effective strategies for improving safety in mining operations. Comprehensive training programs—including safety drills, hazard recognition courses, and proper equipment operation instruction—can drastically reduce risk. Training should be ongoing, not limited to a one-time onboarding process. Companies that invest in continuous training for miners see fewer accidents, higher worker confidence, and better compliance with safety regulations.

Mining Equipment Hazards: Hydraulic Fluids, Tires, and Explosives

Mining equipment hazards pose serious risks on job sites if equipment is not properly maintained or operated. Common mining equipment hazards include hydraulic fluid leaks that can cause fires, damaged tires that may lead to vehicle rollovers, and the improper handling of explosives, which can result in catastrophic incidents. Routine inspections, adherence to manufacturer guidelines, and specialized operator training are essential to minimize these risks.

A Safer Path Forward: Strategies for Reducing Mining Hazards

Reducing hazards requires a multifaceted approach—upgrading equipment, implementing new technologies, improving training, and fostering a strong safety culture. Mines that regularly audit their processes and involve workers in safety planning tend to see the best results.

Safety should be viewed not as a cost, but as an investment in the longevity and reputation of the operation.

Confronting the Cost, Creating Safer Mines

The cost of unsafe mining practices is too high—measured in lives lost, communities impacted, and economic opportunities missed. By prioritizing safety, the mining industry can protect its most valuable asset: its people.

Investing in advanced technology, training programs, and proactive maintenance not only saves lives but also strengthens the industry’s future. The path to safer mines is clear—it begins with commitment, leadership, and the belief that every miner deserves to return home safely.