Noise pollution is a prevalent issue in the mining industry, especially in underground operations. It arises from various sources and significantly affects worker health, safety, and the surrounding environment. This blog delves into the causes, impacts, and solutions to address noise pollution in underground mining, emphasizing the importance of a safer and more sustainable mining industry.

The Sources of Noise in Underground Mining Operations

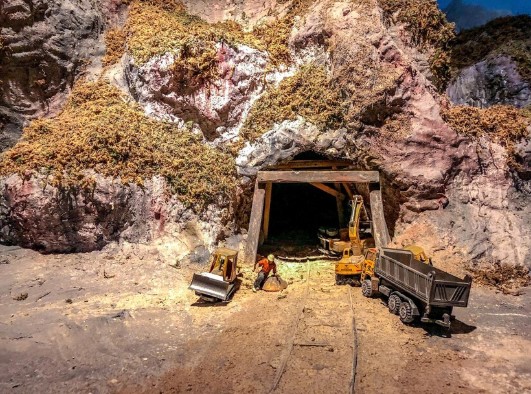

Underground mining involves numerous processes and equipment that contribute to noise pollution. Let’s break down the major sources:

Equipment Operations

Heavy machinery such as drills, loaders, and haul trucks generate significant noise during operations. These machines often operate continuously, amplifying noise exposure for workers.

Ventilation Systems

Proper ventilation is essential for underground mines, but large fans and ducts produce constant, high-decibel noise. These systems are crucial for air circulation but are also one of the primary contributors to background noise.

Rock Blasting

Blasting is a common mining practice to break apart rock, and it produces extremely high noise levels. While momentary, the impact of blasting noise can cause long-term hearing issues for nearby workers.

Conveyor Systems

The movement of materials through conveyor belts adds to the noise levels. The mechanical components of these systems, including rollers and motors, often operate at high decibels.

Impact from Workers

Worker activities such as hammering, shoveling, and operating smaller equipment add to the cumulative noise. Though individual contributions might seem minimal, their combined impact can be significant in enclosed underground spaces.

Health Impacts of Noise Pollution

Exposure to excessive noise in mining operations isn’t just an inconvenience—it’s a health hazard. Prolonged exposure to high-decibel noise can result in:

- Hearing loss or tinnitus.

- Increased stress levels.

- Fatigue and decreased concentration.

- Cardiovascular issues caused by prolonged noise-induced stress.

Worker safety is a top priority in mining, yet noise pollution poses unique challenges. Excessive noise can impair communication, leading to accidents or missteps in hazardous environments. Additionally, workers suffering from hearing loss may struggle to detect warning signals, increasing the likelihood of incidents.

Environmental Consequences of Noise Pollution in Mining Areas

Noise pollution doesn’t just affect workers; it also impacts the surrounding environment. Wildlife in mining areas can experience stress, disrupted communication, and migration due to high noise levels. Nearby communities may also face disturbances, leading to strained relationships between mining companies and local populations.

Regulatory Measures and Standards for Noise Control in Mining

Regulatory bodies like the Mine Safety and Health Administration (MSHA) have established strict guidelines to limit noise pollution in underground mining. These include:

- Mandated use of hearing protection equipment.

- Regular noise monitoring to ensure compliance with permissible exposure limits.

- Implementation of engineering and administrative controls to reduce noise at its source.

Noise Control Technologies and Best Practices for Underground Mines

Modern technology and proactive measures can significantly mitigate noise pollution in underground mining. Some effective strategies include:

- Installing noise-dampening materials on equipment.

- Using quieter machinery designed with advanced engineering controls.

- Enclosing noisy equipment in soundproof barriers.

- Scheduling noisy operations during shifts with fewer workers present.

Case Studies: Successful Noise Reduction in Mining Operations

Several mines worldwide have implemented innovative solutions to reduce noise pollution. For example:

- A coal mine in the United States used acoustic enclosures for their ventilation fans, reducing noise by over 50%.

- In Australia, a gold mine adopted quieter rock drills, which significantly improved worker hearing protection while maintaining productivity.

Future Trends in Managing Noise Pollution in the Mining Industry

The mining industry continues to innovate and adopt forward-thinking approaches to combat noise pollution. Here are some trends shaping the future:

Noise Monitoring

Advanced sensors and IoT devices allow for continuous noise monitoring, providing real-time data to ensure compliance and worker safety.

Engineering Controls

Developing quieter equipment and retrofitting existing machinery with noise-reduction technologies remain key areas of focus.

Operational Changes

Adjusting workflows, such as limiting the simultaneous operation of noisy equipment, can reduce overall noise levels.

Worker Training

Educating workers about the risks of noise pollution and proper use of personal protective equipment (PPE) enhances their safety.

Community Engagement

Mining companies are increasingly engaging with local communities to address concerns about noise pollution. Open communication and transparency help foster trust and collaboration.

Reducing Noise Pollution: Promoting a Safe and Sustainable Industry

Addressing noise pollution in underground mining is critical for the well-being of workers, the environment, and nearby communities. Through technological advancements, regulatory compliance, and proactive strategies, the industry can significantly mitigate noise-related challenges.

By prioritizing noise reduction, mining companies not only protect their workforce but also contribute to a more sustainable and socially responsible industry.