Where the air is thick with potential hazards, respiratory protection is the barrier between miners and harm–like respirable crystalline silica. From futuristic gear to state-of-the-art filtration systems, we’ll uncover how these innovations are driving a new era of protection, compliance, and enhanced respiratory health in mining operations.

Evolution of Respiratory Protection

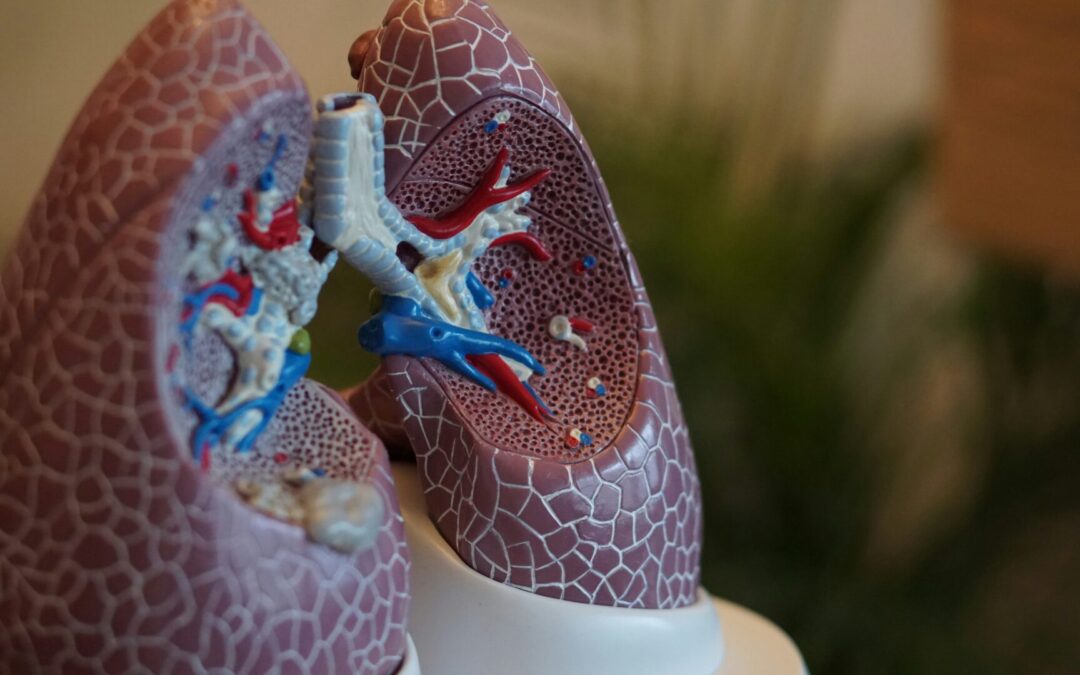

Respiratory protection in mining has evolved significantly over time. Driven by the need to mitigate exposure to hazardous airborne particles, protection has increased. Early forms of protection included basic dust masks, which provided some filtration capabilities against coarse particles but were inadequate for fine particulates like silica dust.

As awareness of occupational health hazards grew, regulatory bodies such as the Mine Safety and Health Administration (MSHA) intervened. By setting standards for respiratory protection in mining environments, miners can feel safe at work. A huge milestone in respiratory protection technology includes the development of NIOSH-certified respirators, such as N95 respirators, P100 respirators, Half-mask respirators, and Full-face respirators, capable of filtering out silica particles effectively.

Regulatory developments have also played a pivotal role in shaping the landscape of respiratory protection in mining. Standards such as the permissible exposure limits (PELs) for silica dust and requirements for respirator fit-testing have been instrumental in ensuring that miners receive adequate protection. Today, advancements in materials science, ergonomic design, and filtration technologies continue to drive innovation in respiratory protection. These advancements cater to the diverse needs of mining operations worldwide.

Types of Respiratory Hazards in Mining

Mining operations expose workers to many respiratory hazards beyond respirable crystalline silica. These include:

- coal dust

- diesel particulate matter (DPM)

- metal fumes

- other toxic gases liberated during drilling, blasting, and material handling processes

Each hazard poses unique challenges to respiratory health. Each requires specialized protection measures tailored to the specific properties of the airborne contaminants.

Coal dust, for instance, is a pervasive hazard in coal mining, capable of causing pneumoconiosis (black lung disease) if inhaled over prolonged periods. Effective control measures, including the use of high-efficiency particulate air (HEPA) filters and regular dust suppression techniques, are extremely effective in mitigating coal dust exposure.

Similarly, diesel-powered equipment emits DPM, which consists of fine particles and gases known to exacerbate respiratory conditions among miners. Luckily, engineering controls such as diesel particulate filters (DPFs) and ventilation systems have proven effective at reducing DPM concentrations in underground mining environments.

Metal mining operations introduce additional respiratory risks due to the generation of metal fumes during ore extraction and processing. Welding and cutting activities further contribute to airborne contaminants, necessitating the adoption of respiratory protection strategies that address both particulate and chemical exposures. By understanding the specific hazards present in their operations, mining companies can implement targeted respiratory protection solutions. These solutions prioritize worker safety and compliance with regulatory standards.

Advancements in Respirator Design and Functionality

Innovative respirator technologies are revolutionizing respiratory protection in mining. This offers enhanced comfort, usability, and protection levels for miners exposed to hazardous airborne particles. These ergonomic designs, lightweight materials, and enhanced seals ensure a better fit and reduce the risk of exposure. Modern respirators are designed to meet stringent NIOSH standards and MSHA regulations, ensuring optimal filtration efficiency and durability in challenging mining environments.

Additionally, modern respirators are now equipped with cutting-edge filtration technology. This technology not only blocks harmful contaminants but also offers greater breathability and comfort. Miners are then allowed to wear them for extended periods without discomfort. In fact, new features like integrated communication systems and real-time monitoring of air quality are empowering miners to stay connected and informed, further elevating the standards of safety underground.

One example is powered air-purifying respirators (PAPRs). These respirators represent a significant advancement in respiratory protection. Particularly in settings where prolonged exposure to airborne contaminants is unavoidable. PAPRs use a battery-powered blower to draw air through a filter, delivering a continuous supply of clean air to the wearer. This technology reduces breathing resistance and minimizes heat buildup, enhancing comfort and user acceptance among miners working long shifts underground.

Training and Compliance

Technology has come a far way, but all of it is obsolete if workers don’t utilize it correctly. Effective use of respiratory protection hinges on rigorous training programs and adherence to MSHA regulations governing respirator use in mining operations. Comprehensive training educates miners on the hazards associated with silica dust and other airborne contaminants. This training emphasizes proper respirator selection, donning and doffing procedures, and maintenance protocols.

Fit-testing protocols are integral to ensuring that respirators provide a tight seal against the wearer’s face, minimizing inward leakage of contaminated air. Quantitative fit-testing methods, such as the use of ambient aerosol condensation nuclei counters (CNCs), provide objective measurements of respirator fit and help identify suitable respirator models for individual miners.

Then there’s the upkeep. Regular maintenance and inspection of respirators are essential in preserving their effectiveness and extending service life. Cleaning procedures, storage practices, and routine replacement of filters and cartridges prevent degradation of filtration performance and ensure that respirators remain compliant with NIOSH certification requirements.

Future Trends in Respiratory Protection

Looking ahead, emerging trends in respiratory protection hold promise for further enhancing safety and efficiency in mining operations. The future of respiratory protection is set to be shaped by cutting-edge advancements that prioritize both safety and comfort.

Smart respirators equipped with sensor technologies offer real-time monitoring of airborne contaminants. These respirators alert miners to hazardous exposure levels and suggest immediate corrective actions. These devices integrate data analytics capabilities, enabling mining companies to track respiratory health trends and optimize workplace safety protocols based on actionable insights.

Innovations in materials are also leading to lighter, more breathable designs that enhance wearability without compromising protection. Additionally, the integration of artificial intelligence and machine learning into respiratory systems could offer personalized protection plans, adapting to individual needs and specific work environments.

While safety and efficiency are top priority, research initiatives are also focused on advanced filtration materials and sustainable respirator designs. The designs aim to reduce environmental impact while maintaining high standards of respiratory protection. Collaborations between industry stakeholders, research institutions, and regulatory agencies are driving innovation in respiratory protection, fostering a culture of continuous improvement and proactive risk management in mining operations.

The Road Ahead: Empowering Miners with the Future of Respiratory Protection

Innovations in respiratory protection have come a long way, and it doesn’t look like it’s stopping anytime soon. With the advent of AI, machine learning, and other smart technology, there’s plenty to come.

These cutting-edge innovations in respiratory protection are vital in the ongoing mission to protect miners’ health as occupational hazards continue to evolve. By harnessing the power of new technology and putting respiratory safety at the forefront, mining companies can significantly reduce the dangers posed by respirable crystalline silica and other airborne threats. This proactive approach ensures that every miner steps into a safer, healthier work environment—where their well-being is always a top priority.

What will it take? Continued collaboration, research investment, and adherence to regulatory standards, to name a few. Together, we can empower miners with the tools and knowledge needed to protect their respiratory health and uphold industry-leading safety standards.