Underground mining plays a pivotal role in supplying the world with essential minerals and materials, but it comes with significant financial implications. From the initial investment to ongoing operational expenses, the cost of underground mining requires careful consideration. This guide explores the many factors influencing these costs and how companies can navigate them effectively while ensuring profitability and sustainability.

Factors Influencing Underground Mining Costs

The expenses associated with underground mining are shaped by a range of variables, including the depth of the deposit, the geology of the area, and the technology employed. Each mine is unique, requiring tailored strategies for cost management. These factors contribute to a complex financial framework that businesses must understand to succeed.

Initial Investment and Capital Expenditure

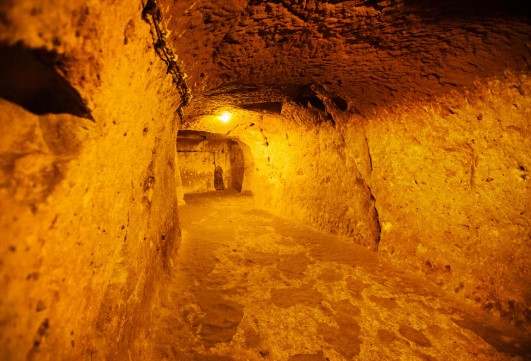

Starting an underground mining operation involves significant upfront costs. The capital required for site exploration, development, and infrastructure construction often runs into millions of dollars. Building shafts, tunnels, and ventilation systems are among the most expensive aspects of underground mining.

Furthermore, the procurement of specialized equipment adds to the initial investment. This equipment is not only costly to purchase but also requires regular maintenance to ensure efficient operations.

Operational Costs in Underground Mining

Day-to-day operations in underground mining are resource-intensive. These include the costs of electricity for lighting, ventilation, and machinery operation, as well as expenditures for fuel and consumables such as explosives and safety equipment.

The need for ongoing safety and maintenance checks also increases operational expenses. Regular inspections, equipment repairs, and contingency plans are critical to avoiding costly downtime or accidents.

Labor Costs and Workforce Considerations

Labor is one of the most substantial components of the cost of underground mining. The sector requires a highly skilled workforce, including miners, engineers, safety officers, and support staff. These professionals often work in hazardous conditions, which justifies higher wages and comprehensive benefits packages.

Training programs to ensure worker safety and efficiency further add to labor expenses. Retaining skilled employees is vital to maintaining operational consistency and minimizing recruitment costs.

Equipment and Technology Expenses

Modern underground mining heavily relies on advanced equipment and technology, such as automated drilling systems, GPS tracking, and ventilation control systems. While these innovations improve efficiency and safety, they come with a hefty price tag.

Additionally, as technology evolves, companies must continuously upgrade their equipment to stay competitive. This includes not only the cost of new machinery but also the training required for employees to use it effectively.

Regulatory and Compliance Costs

Mining companies must comply with stringent regulations governing worker safety, environmental protection, and operational standards. Meeting these requirements often involves substantial financial outlays.

From obtaining permits and licenses to conducting regular audits and implementing safety protocols, compliance costs can significantly impact the overall budget. Non-compliance, on the other hand, can result in fines, legal battles, and reputational damage.

Environmental Impact and Remediation Costs

Underground mining inevitably impacts the surrounding environment, and addressing these effects comes at a cost. Companies are often required to invest in land rehabilitation, water treatment, and pollution control measures.

Long-term environmental monitoring and community engagement initiatives also contribute to these expenses. While these efforts are essential for sustainability, they add to the financial burden of mining operations.

Regional Variations in Mining Costs

The cost of underground mining varies significantly depending on the location of the mine. Factors such as local labor rates, energy costs, and the availability of infrastructure play a critical role.

Mines located in remote areas often face higher logistical expenses, including transportation of equipment and materials. Political and economic stability in the region also influences operating costs, with unstable regions typically incurring higher risks and expenses.

Cost-Benefit Analysis of Underground vs. Surface Mining

While underground mining offers access to deeper deposits and often yields higher-quality materials, it is generally more expensive than surface mining. Companies must conduct a thorough cost-benefit analysis to determine the most viable option for their projects.

Factors such as deposit depth, ore quality, and environmental impact must be weighed against the financial and logistical demands of each method. While underground mining may cost more upfront, its potential for higher returns can make it a worthwhile investment.

Future Trends and Innovations in Cost Management

Advancements in technology are paving the way for more efficient and cost-effective underground mining operations. Automation, artificial intelligence, and renewable energy integration are transforming the industry, reducing labor and energy costs while improving safety and productivity.

Additionally, blockchain technology is being explored for better supply chain management, while predictive analytics help companies anticipate and mitigate potential expenses. These innovations are crucial for maintaining profitability in a competitive and evolving market.

Navigating the Complexities of Underground Mining Costs

The cost of underground mining is influenced by a multitude of factors, from initial investments and operational expenses to environmental and regulatory requirements. By understanding these complexities and leveraging innovative technologies, companies can effectively manage costs while maximizing profitability.

As the mining industry continues to evolve, balancing economic viability with sustainability will remain a priority. By adopting forward-thinking strategies, businesses can thrive in this challenging yet rewarding sector.